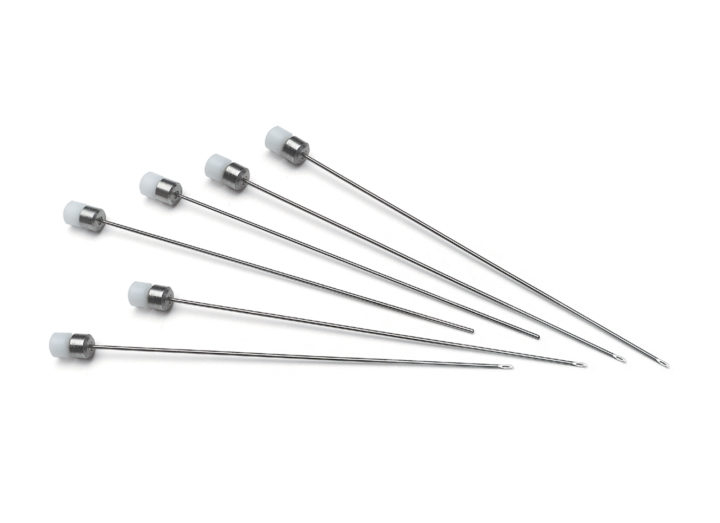

Needles

-

-

-

- Manufacturers: Hamilton®

- Brand: Hamilton®

- SECO Part No: HC-7779-02

- Sold As: 6/Pack

- Manufacturer Part No: 7779-02

-

Availability:

- Minimum order quantity: 1

- Qty. Interval: 1

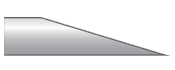

Hamilton® 7779-02

Removable Needle, 51 mm L, 0.12 ID x 0.47 mm More...

-

Login to View Your Price

List Price :

-

Add to cart

-

-

-

-

- Manufacturers: Hamilton®

- Brand: Hamilton®

- SECO Part No: HC-7762-06

- Sold As: 6/Pack

- Manufacturer Part No: 7762-06

-

Availability:

- Minimum order quantity: 1

- Qty. Interval: 1

Hamilton® 7762-06

Removable Needle, 38.1 mm, 0.11 ID x 0.21 mm More...

-

Login to View Your Price

List Price :

-

Add to cart

-

-

-

-

- Manufacturers: Hamilton®

- Brand: Hamilton®

- SECO Part No: HC-7780-01

- Sold As: 6/Pack

- Manufacturer Part No: 7780-01

-

Availability:

- Minimum order quantity: 1

- Qty. Interval: 1

Hamilton® 7780-01

Removable Needle, 51 mm L, 0.12 ID x 0.47 mm More...

-

Login to View Your Price

List Price :

-

Add to cart

-

-

-

-

- Manufacturers: Hamilton®

- Brand: Hamilton®

- SECO Part No: HC-90539

- Sold As: 6/Pack

- Manufacturer Part No: 90539

-

Availability:

- Minimum order quantity: 1

- Qty. Interval: 1

Hamilton® 90539

Luer Lock Needle, 51 mm L, 0.12 ID x 0.47 mm More...

-

Login to View Your Price

List Price :

-

Add to cart

-

-

-

-

- Manufacturers: Hamilton®

- Brand: Hamilton®

- SECO Part No: HC-8651-01

- Sold As: 6/Pack

- Manufacturer Part No: 8651-01

-

Availability:

- Minimum order quantity: 1

- Qty. Interval: 1

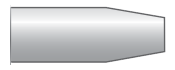

Hamilton® 8651-01

Replacement Gel Loading Needle, 0.2 OD x 25.4 More...

-

Login to View Your Price

List Price :

-

Add to cart

-

-

-

-

- Manufacturers: Hamilton®

- Brand: Hamilton®

- SECO Part No: HC-7787-01

- Sold As: 6/Pack

- Manufacturer Part No: 7787-01

-

Availability:

- Minimum order quantity: 1

- Qty. Interval: 1

Hamilton® 7787-01

Replacement Needle, 19.1 mm L, 0.15 ID x 0.71 More...

-

Login to View Your Price

List Price :

-

Add to cart

-

-

-

-

- Manufacturers: Hamilton®

- Brand: Hamilton®

- SECO Part No: HC-7758-02

- Sold As: 6/Pack

- Manufacturer Part No: 7758-02

-

Availability:

- Minimum order quantity: 1

- Qty. Interval: 1

Hamilton® 7758-02

Removable Needle, 51 mm L, 0.12 ID x 0.47 mm More...

-

Login to View Your Price

List Price :

-

Add to cart

-

-

-

-

- Manufacturers: Hamilton®

- Brand: Hamilton®

- SECO Part No: HC-7786-01

- Sold As: 6/Pack

- Manufacturer Part No: 7786-01

-

Availability:

- Minimum order quantity: 1

- Qty. Interval: 1

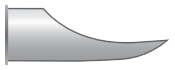

Hamilton® 7786-01

Replacement Needle, 43 mm L, 23s ga, AS Point More...

-

Login to View Your Price

List Price :

-

Add to cart

-

-

-

-

- Manufacturers: Hamilton®

- Brand: Hamilton®

- SECO Part No: HC-90033

- Sold As: 6/Pack

- Manufacturer Part No: 90033

-

Availability:

- Minimum order quantity: 1

- Qty. Interval: 1

Hamilton® 90033

Luer Lock Needle, 51 mm L, 0.11 ID x 0.21 mm More...

-

Login to View Your Price

List Price :

-

Add to cart

-

-

-

-

- Manufacturers: Hamilton®

- Brand: Hamilton®

- SECO Part No: HC-8648-01

- Sold As: 6/Pack

- Manufacturer Part No: 8648-01

-

Availability:

- Minimum order quantity: 1

- Qty. Interval: 1

Hamilton® 8648-01

Replacement Needle, 50 mm L, 0.15 ID x 0.51 m More...

-

Login to View Your Price

List Price :

-

Add to cart

-

-

-

-

- Manufacturers: Hamilton®

- Brand: Hamilton®

- SECO Part No: HC-90139

- Sold As: 6/Pack

- Manufacturer Part No: 90139

-

Availability:

- Minimum order quantity: 1

- Qty. Interval: 1

Hamilton® 90139

Luer Lock Needle, 51 mm L, 0.12 ID x 0.47 mm More...

-

Login to View Your Price

List Price :

-

Add to cart

-

-

-

-

- Manufacturers: Hamilton®

- Brand: Hamilton®

- SECO Part No: HC-210548

- Sold As: 1/Pack

- Manufacturer Part No: 210548

-

Availability:

- Minimum order quantity: 1

- Qty. Interval: 1

Hamilton® 210548

Venting Needle, 51 mm L, Stainless Steel, 0.5 More...

-

Login to View Your Price

List Price :

-

Add to cart

-