What the heck are boiling flasks?

Boiling flasks are laboratory glassware primarily used for heating, mixing, and storing liquids. They are commonly found in chemical, biological, and pharmaceutical labs, where precise and safe handling of volatile or reactive substances is required. The main types of boiling flasks are:

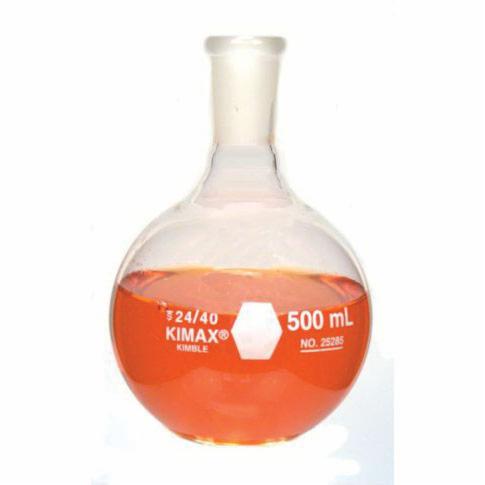

Round bottom flasks: These have a spherical bottom, which allows for more uniform heating of the liquid inside. Their shape is particularly useful when heat needs to be distributed evenly, such as during distillation or when the flask is heated with a Bunsen burner or heating mantle. The rounded design also facilitates easier stirring or swirling of the contents.

Flat bottom flasks: These can stand on their own without support, making them suitable for use on hotplates or other flat heating surfaces. They are versatile and can be used for reactions that require heating as well as for simple storage of solutions.

What liquids are commonly heated in boiling flasks?

Boiling flasks drink down a wide range of liquids. There are literally thousands of possibilities. But some are much more common than others, like:

- Water: Often used as a solvent or for heating purposes in processes.

- Ethanol: Commonly used as a solvent in organic chemistry due to its ability to dissolve many organic compounds.

- Hydrochloric acid (HCl): Frequently used in chemistry labs for titrations, preparing samples, and adjusting pH levels.

- Sodium hydroxide (NaOH) solution: Used in chemical reactions requiring a strong base or for cleaning purposes.

- Acetone: Utilized as a solvent, especially in cleaning glassware to remove organic residues.

- Buffer solutions: Used to maintain a constant pH in biochemical and chemical reactions.

- Distilled organic compounds: Such as benzene, toluene, or other hydrocarbons used in synthesis and analysis.

- Culture media: For growing bacteria, yeast, or other microorganisms in microbiology.

- Indicator solutions: Used in titrations to visualize the end point of a reaction.

- Salt solutions: Such as sodium chloride or magnesium sulfate, used in various chemical and biological experiments.

These liquids cover a broad range of applications, from simple rinsing and solvent actions to more complex reactions and biological cultures. But, of course, your application might use none of these.

How are you using your boiling flasks?

Some of the most common applications our customer use boiling flasks in are:

- Solvent removal in the herbal industry: Used to evaporate solvents like ethanol during the extraction and purification of herbal oils.

- Chemical synthesis: Employed in the synthesis of chemicals, where controlled reactions are necessary under heat.

- Distillation processes: Integral in setups for distilling compounds, particularly in organic chemistry labs to purify liquids.

- Sample preparation in environmental testing: Used to prepare samples by heating and mixing, often in testing for pollutants or contaminants.

- Culturing microorganisms: Used in microbiology to grow and maintain cultures in a liquid medium, under controlled temperature conditions.

- Pharmaceutical research: Employed for the development and testing of new drug formulations, where precise temperature control is essential.

- Educational demonstrations: Commonly used in educational settings for demonstrating chemical reactions and basic distillation techniques.

- Material science research: Used to mix and heat solutions when studying material properties under various conditions.

- Quality control in food and beverage Industries: Used to test samples and ensure consistency and safety in food products.

- Organic extraction procedures: Utilized in extracting organic compounds from mixtures via heating, often followed by separation techniques.

Why do some boiling flasks have angled necks?

Some boiling flasks feature angled necks, offering several unique advantages:

- ✔ Improved efficiency: Easier access for attaching additional apparatus and reducing the risk of spills.

- ✔ Reduced contamination: Minimizes the risk of accidental contamination during transfers.

- ✔ Enhanced safety: Provides protection from hazardous vapors or splashes.

- ✔ Versatile applications: Ideal for setups requiring vertical alignment of glassware.

- ✔ Improved stirring and mixing: Allows for better agitation of flask contents

Applications and uses of distillation flasks?

Distillation flasks are indispensable tools in various scientific and industrial applications. Their designs and materials make them suitable for a range of uses that require precision, durability, and chemical resistance. Key applications for distillation flasks can include:

- Organic synthesis

Application: Distillation flasks are essential in organic synthesis processes, where they facilitate the purification and separation of chemical compounds.

Use: They help in removing solvents and isolating desired products by heating mixtures to their boiling points and condensing the vapors. - Purification of liquids

Application: Used extensively in the purification of liquids, distillation flasks enable the separation of components based on their boiling points.

Use: Commonly employed in the purification of solvents, essential oils, and other volatile substances to achieve high-purity results. - Fractional distillation processes

Application: In fractional distillation, distillation flasks are crucial for separating mixtures into individual components.

Use: This method is particularly useful in refining petroleum products, separating alcohols, and producing high-purity chemicals for industrial and laboratory use. - Chemical analysis

Application: Analytical chemistry relies on distillation flasks for various quantitative and qualitative analyses.

Use: They concentrate samples, remove impurities, and prepare reagents, ensuring accurate and reliable analytical results. - Pharmaceutical prep

Application: Distillation flasks play a vital role in pharmaceutical laboratories for the preparation of drugs and active pharmaceutical ingredients (APIs).

Use: They help in the extraction, purification, and concentration of medicinal compounds, ensuring the efficacy and safety of pharmaceutical products. - Environmental testing

Application: Environmental testing labs use distillation flasks to prepare and analyze samples for pollutants and contaminants.

Use: They facilitate the concentration of samples, removal of solvents, and isolation of analytes for accurate environmental monitoring. - Food and bev

Application: The food and beverage industry uses distillation flasks for flavor extraction and quality control.

Use: They distill essential oils, extracts, and flavor compounds, ensuring consistent quality and safety in food products.

Why stop a distillation before the pot flask goes dry?

You stop distillations in your distillation flask before it goes dry for equipment safety, product integrity, and overall laboratory safety.

Preventing damage to equipment is a significant reason to avoid letting the pot flask go dry. Allowing the flask to run dry can cause thermal shock due to the sudden change in temperature, potentially leading to cracking or breaking of the glassware. This risk is present even with borosilicate glass, which, while durable, can still be vulnerable to extreme temperature changes. Additionally, a dry flask can overheat, causing damage to heating mantles, hot plates, or other heating elements used in the distillation setup, posing safety hazards and risking equipment damage.

Safety concerns are another critical factor. The residue left in the flask can decompose or react dangerously when heated without any liquid to absorb the heat, leading to pressure build-up and potential explosion. Moreover, certain residues may become flammable or combustible when the liquid is completely evaporated, posing a significant fire risk.

Maintaining product integrity is essential during distillation. When the distillation flask runs dry, residues can decompose and contaminate the distilled product, affecting its purity and quality. This is particularly critical in applications requiring high-purity distillates, such as in pharmaceuticals or fine chemicals. Additionally, some components may be more volatile than others. As the liquid level decreases, these volatile components might distill over and contaminate the receiving flask, resulting in impure fractions.

Avoiding residue buildup is important for the maintenance and longevity of the equipment. A dry flask often leaves behind a solid residue that can be difficult to clean. Residues from organic compounds can carbonize and adhere strongly to the flask, requiring harsh chemicals or mechanical scraping to remove. This can interfere with future distillations if not properly cleaned, leading to cross-contamination of products.

Why is a round-bottomed flask used in distillation?

A round-bottomed distillation flask is widely used due to its design and material properties, which offer several advantages over other types of flasks.

Even heating is one of the primary reasons for using a round-bottomed flask in distillation. The spherical shape of the flask allows for uniform distribution of heat when the flask is placed in a heating mantle or over a Bunsen burner. This uniform heating helps in achieving a consistent boiling rate, which is crucial for efficient distillation. Unlike flat-bottomed flasks, which can have hot spots leading to uneven boiling and potential bumping, round-bottomed flasks provide a smooth, even surface for heat transfer.

Mechanical strength is another significant advantage. The round shape of the flask distributes mechanical stress evenly across its surface, making it less likely to crack or break under pressure or during thermal expansion. This makes round-bottomed flasks more durable and safer to use in high-temperature distillation processes, where rapid temperature changes are common.

Efficient mixing is facilitated by the shape of the round-bottomed flask. When stirring the contents, either manually or with a magnetic stirrer, the rounded base allows for better circulation and mixing of the liquid. This is particularly important in distillations that require uniform mixing of reactants to prevent localized overheating and ensure complete reactions.

Easy cleaning is another practical benefit of round-bottomed flasks. The smooth, curved interior surface minimizes the accumulation of residues and makes it easier to clean thoroughly after use. This is especially useful in laboratories where cross-contamination must be avoided, and maintaining clean equipment is essential for accurate results.

Adaptability to various setups is also a key factor. Round-bottomed flasks typically come with standard taper joints, allowing them to be easily connected to other glassware, such as condensers, adapters, and receivers, forming a tight, leak-proof seal. This versatility makes them suitable for a wide range of distillation setups and applications, from simple to complex fractional distillations.

Reduced risk of bumping is an important safety consideration. The shape of the round-bottomed flask helps in the formation of nucleation sites, which promotes smooth boiling and reduces the risk of bumping. Bumping can cause sudden, violent eruptions of liquid, which are hazardous and can lead to loss of material and contamination of the distillate.

Read this far and still can’t decide what you need?

Give us a call to talk about what your lab needs. We have an extensive offline catalog that likely has everything you need and more.